Diverse Printing Capabilities

Tursso manages all aspects of your project, making the entire production process seamless from design to print.

Change is the new constant. With Tursso’s broad experience and diverse printing capabilities, we help our customers stay on top of consumer demands, market trends and a complex regulatory landscape with innovation, flexibility and speed. In order to accommodate a wide variety of packaging needs and orders of varying size and complexity, Tursso continues to invest in traditional and digital printing technologies, along with streamlined prepress processes. We strive to provide printed products at the highest quality and value for our customers worldwide.

Digital Solutions

Digital printing yields exceptional printing quality and turnaround speed. Requiring fewer steps in the manufacturing process, less waste, and no plate costs, digital printing allows brands to quickly and economically adapt to evolving trends and regulatory changes. Whether developing prototypes, or showcasing the latest flavor, fragrance, or colorway, Tursso’s digital printing solutions provide speed, quality and limitless customization possibilities.

The HP Indigo Advantage

Tursso’s HP Indigo digital printing capabilities allow for broad customizations and color options while increasing brand security and traceability. Here’s a quick snapshot of what Tursso can offer with our HP digital capabilities:

- Create personalized one-of-a-kind variable images and text within a single print run

- Safeguard against counterfeiting with high-definition covert security features

- Boost traceability with inline variable data and serialization features

- Reach beyond CMYK with 7 color stations to achieve precise color targets

- Elevate designs using HP Indigo Silver ink to achieve metallic effects

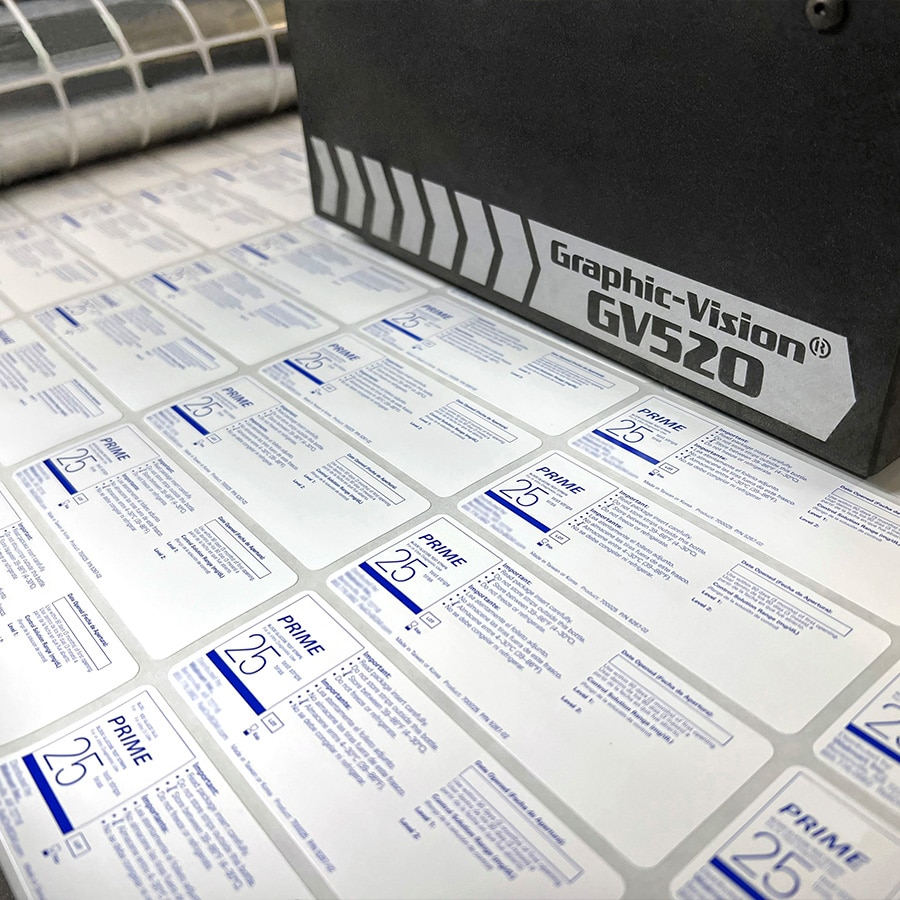

Flexographic Printing

Considered one of the most versatile and economical printing solutions for medium to large-volume production orders, Flexographic Printing combines printing, finishing, diecutting and other processes into a single press pass. What was once a rudimentary printing process has evolved steadily over decades, now rivaling other printing technologies in quality and sophistication. Flexography allows for fast, cost-effective production of Pressure Sensitive Labels, Expanded Content Labels, Flexible Packaging and other unique packaging components.

Lithographic Printing Solutions

Commonly used to print booklets, leaflets, and other informational materials, lithographic printing earns its favorable reputation by yielding sharp image and text quality and overall product consistency. Lithographic printing is also known for being increasingly cost-effective the more you print. If you need instructions for use inserts, outserts or booklets, cartons, tags or other printed materials, Tursso is ready to assist with best-in-class lithographic printing services. We have the flexibility to support large volume production, as well as small orders for new product launches and FDA qualification runs.

In-House Prepress and Platemaking

As important members of the job planning team, our prepress technicians work closely with project managers and the pressroom. Then, using the latest software and streamlined workflows, they prepare your artwork for a successful printed outcome. We utilize PDF soft proofing to accelerate the proof approval process, and can provide full color Epson proofs or digital press proofs when needed. In addition, our Prepress team can create working prototypes and full color presentation mock-ups so you can validate design decisions, verify specifications, and obtain stakeholder approval before moving into full scale production. The success of your printed project demands careful planning, proof execution and version control, and Tursso’s in-house Prepress team leaves nothing to chance.